Forging

Our products, through precise design, not only improve material utilization but also enhance the mechanical performance of metals using cold working techniques, making them more durable and resilient.

Forging Product Catalogue,Spec. M3-M120

Hex Bolt and Nut

Grade: SAE2-SAE8, 4.8-14.9

Surface: blackened, galvanised, HDG, Dacromet...

Socket head cap screws

Grade: SAE2-SAE8, 4.8-14.9

Surface: blackened, galvanised, HDG, Dacromet...

12-spline flange bolts

Grade: SAE2-SAE8, 4.8-14.9

Surface: blackened, galvanised, HDG, Dacromet...

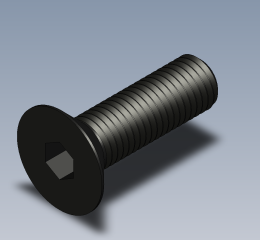

Socket Countersunk Head Screws

Grade: SAE2-SAE8, 4.8-14.9

Surface: blackened, galvanised, HDG, Dacromet...

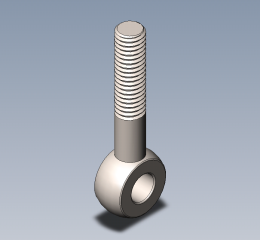

Eye Bolt

Grade: SAE2-SAE8, 4.8-14.9

Surface: blackened, galvanised, HDG, Dacromet...

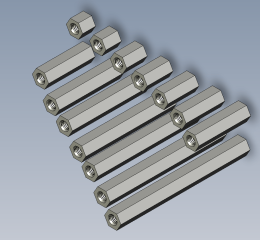

Hexagon coupling nuts

Grade: SAE2-SAE8, 4.8-14.9

Surface: blackened, galvanised, HDG, Dacromet...

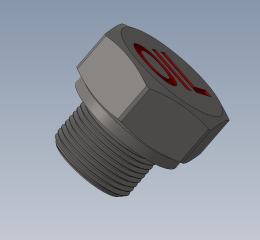

Hexagon Head Plug

Grade: SAE2-SAE8, 4.8-14.9

Surface: blackened, galvanised, HDG, Dacromet...

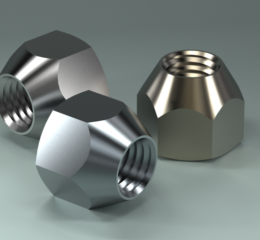

Wheel Nut

Grade: SAE2-SAE8, 4.8-14.9

Surface: blackened, galvanised, HDG, Dacromet...

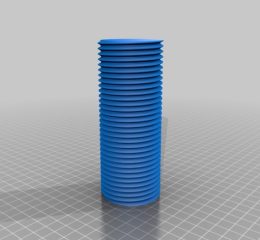

Stud

Grade: SAE2-SAE8, 4.8-14.9

Surface: blackened, galvanised, HDG, Dacromet...

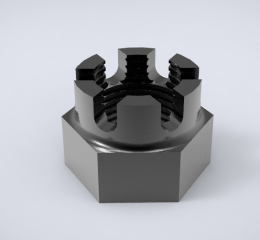

Hexagon Slotted Nuts

Grade: SAE2-SAE8, 4.8-14.9

Surface: blackened, galvanised, HDG, Dacromet...

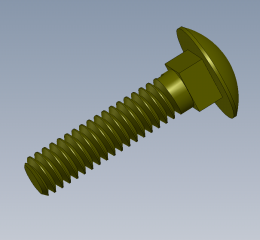

Cup Head Square Neck Bolts

Grade: SAE2-SAE8, 4.8-14.9

Surface: blackened, galvanised, HDG, Dacromet...

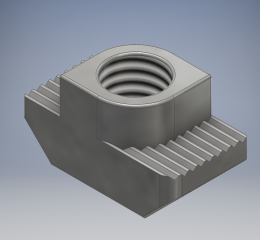

Nuts For T-Slot

Grade: SAE2-SAE8, 4.8-14.9

Surface: blackened, galvanised, HDG, Dacromet...

The cold heading (extrusion) method of processing fasteners and special-shaped parts is a processing method with high comprehensive economic benefits. It is widely used in the fastener industry and is an advanced processing method that is widely used and rapidly developing at home and abroad. Our factory can produce products according to various standards including ISO, ASTM, IFI, DIN, AS, BS, GB, JIS, GOST, EN, etc., and also customizes according to drawings. We use materials such as low carbon steel, medium carbon steel, alloy steel, and stainless steel for production. The product grades cover 4.8-14.9, and they have strong corrosion resistance and wear resistance on the surface.

Highlights of Technology:

- High Material Utilization: The new process of “recessed” hex head bolts achieves a material utilization rate of over 99%.

- High Production Efficiency: Compared to traditional cutting processes, production rates increase by 25 to 30 times.

- Excellent Surface Finish: General surface finish reaches V5, and special requirements can achieve V6.

- Precision Assurance: Suitable for large-scale production, ensuring precision.

Our cold heading technology is a revolution in the fastener industry and a reliable choice. Choosing us means selecting both quality and efficiency.